MSME manufacturers, are you prepared to tackle the challenges of the evolving

manufacturing landscape? Your customers are embracing digital manufacturing

- are you in sync with their vision? To foster growth, it's essential to collaborate

with your customers on their growth path.

At OpExWorks, our commitment lies in transforming MSME manufacturing by

providing extensive, scalable digital solutions customized to align with global

standards.

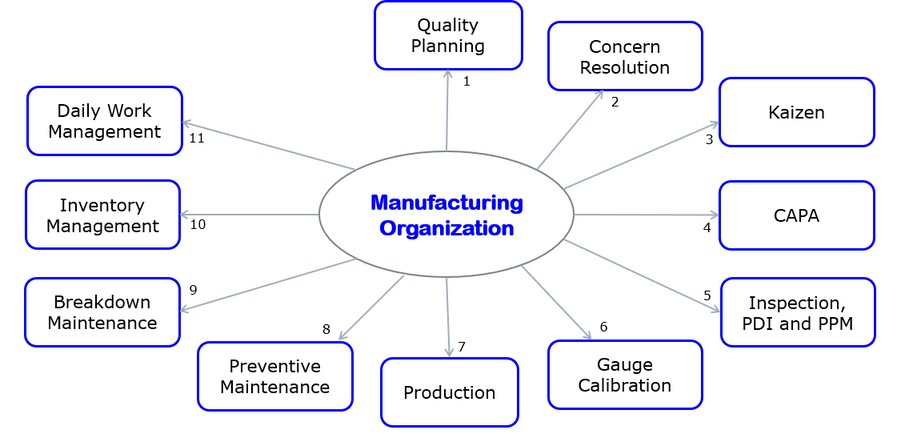

OpExWorks RIYO MES, a Manufacturing Execution System, comprises 11 essential modules necessary for any manufacturing company.

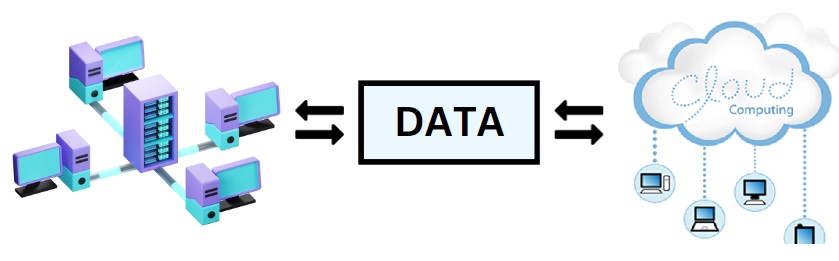

Smoothly incorporate RIYO MES by creating and launching data interfaces to seamlessly integrate with your current software systems.

Link your equipment and devices in the plant by choosing your IoT partner wisely. With RIYO MES, data integration into MES becomes seamless, enabling genuine digitalization and the adoption of cutting-edge systems.

Choose modules according to your business objectives, goals, and priorities. You can decide to incorporate RIYO MES into particular modules or deploy it as a fully integrated system.

RIYO’s Quality Planning module ensures compliance with AIAG standards, enhancing product quality and consistency. It simplifies the management and revision of quality documents, reducing errors and improving operational efficiency, crucial for manufacturing companies aiming to meet stringent quality benchmarks.

The Concern Resolution framework in RIYO facilitates systematic problem-solving, from registration through root cause analysis to improvement. It helps manufacturing companies efficiently address issues related to suppliers, in-plant operations, or customer complaints, enhancing reliability and customer satisfaction.

RIYO’s Kaizen module promotes continuous improvement and operational efficiency, crucial for manufacturing companies. It supports incremental changes that streamline processes, reduce waste, and boost productivity, fostering a culture of ongoing enhancement and employee engagement in problem-solving.

The CAPA module in RIYO helps manufacturing companies proactively address and prevent issues, ensuring compliance and improving operational reliability. By systematically resolving root causes, it enhances product quality, reduces risks, and fosters a culture of continuous improvement.

RIYO’s Inspection, Pre-Delivery Inspection (PDI), and Process Performance Monitoring (PPM) modules ensure rigorous quality checks and compliance, crucial for manufacturing companies to maintain high-quality standards. These tools help minimize defects, enhancing product reliability and customer trust.

The Gauge Calibration module ensures precision and compliance in measurements, critical for quality control in manufacturing. For manufacturing companies, it supports maintaining equipment accuracy, enhancing product quality, and building customer confidence through reliable outputs.

RIYO’s Production module helps manufacturing companies optimize their production processes through real-time insights and data-driven decision-making. It enhances productivity, reduces downtime, and supports lean manufacturing practices, aligning with the strategic goals of manufacturing companies for higher operational excellence.

Preventive Maintenance in RIYO reduces unplanned downtime and extends equipment life by scheduling regular maintenance checks. This is vital for manufacturing companies to ensure consistent production output and reduce maintenance costs by preventing major equipment failures.

The Breakdown Maintenance module quickly addresses equipment failures, minimizing production delays. For manufacturing companies, it enhances equipment availability and operational efficiency, crucial for maintaining continuous manufacturing processes and meeting production targets.

RIYO’s Inventory Management module optimizes stock levels and improves resource utilization, essential for manufacturing companies to minimize waste and reduce inventory costs. It integrates seamlessly with production and quality modules to enhance overall operational efficiency.

This module provides manufacturing companies with tools to streamline daily operations, monitor key performance indicators, and enhance employee productivity. It supports standardizing work procedures, tracking tasks in real time, and driving continuous improvement, essential for maintaining competitive advantage in fast-evolving markets.

In a factory setting, being tied to a desk all day is not feasible. That's why RIYO offers modules that allow operations to be carried out on mobile handheld devices, ensuring uninterrupted and timely access.

Concentrate on your niche and entrust software to OpExWorks. It's impossible to be experts in every field. While you leverage your expertise to offer optimal solutions to customers, we will deliver top-notch software for seamless integration with your system. Collaborating with OpExWorks will enhance the value you bring to your customers..

Automation Companies

RIYO MES enhances manufacturing automation with streamlined production, predictive maintenance, and real-time analytics. It offers automation companies a tool to boost client efficiency and operational compliance, ensuring a competitive edge.

System Integrators

RIYO MES integrates smoothly with existing systems, providing system integrators a scalable solution to enhance client operations with advanced functionalities for manufacturing execution, ensuring improved productivity and compliance

With over 500 customers in the past 8 years, our commitment to lifetime

partnerships is unwavering. We take joy in being a part of our customers'

journey by offering cutting-edge technology solutions that align with their vision

and growth strategies.

Join us as we collaborate to bring the utmost value to end customers and aim

for customer satisfaction. Our clientele ranges from tiny startups to large

enterprises, encompassing all sizes in between.

Kindly fill out the form below, and our team will contact you shortly..