The components required in the application of Low Cost Automation can be classified into those required for 'Work Elements’, Control Elements', and 'Sensing Elements', and for storage of energy. The components generally used are:

Some of the components are briefly described here.

Pneumatic and hydraulic cylinders are ideal for mechanical handling and automatic processing applications which require linear motions. They have many advantages such -as simple in construction, rugged, can, withstand severe overloads and provide for easy control of speeds. A cylinder is the most commonly used device to convert fluid power into mechanical work or power. A cylinder can be single acting or double acting and plunger or piston type. Cylinders can also be classified by function, such as 'impact', 'telescopic', and according to lounging, such as 'flange mounted', turn on mounted', 'foot mounted', and ‘hinge mounted, etc.

Pneumatic and Hydraulic motors are used to provide rotary motions. Air motors are compact and require little maintenance. Their speed can readily be adjusted by varying the pressure of air supply by a regulator. They are not damaged by overload.

In air motors, there are 3 types, viz., vane type, piston type and diaphragm type.

Rotary actuators are used for indexing, locating, clamping, etc. They are generally applied where rotary motions of limited rotation, high torque are needed.

Valves are basically classified as

Valves are basically classified as (1) Directional Control Valves (2) Pressure Control Valves and (3) Accessory Valves. Valves are generally specified by (1) the number of ports or connections (2) the number of positions, and (3) the methods cooperation, i.e., whether manual, mechanical, pneumatic, hydraulic, vacuum or electrical. The simplest type of valve is the two-Port, two position valves. This valve is a simple on off control which can, be used for starting and stopping a machine. The function is similar to an electrical contact, which is either open or closed.

Pressure control valves include pressure relief valves and pressure reducing valves. Accessory valves include non-return valves, shuttle valves, flow control valves and sequence valves.

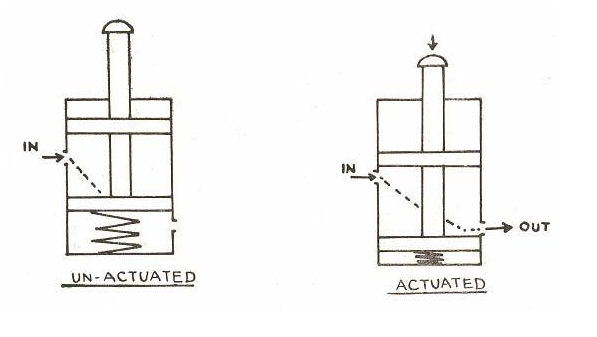

A simple two-port, two position, manually operated, spring returned' valve is shown in the figure below:

Fig. Manually operated, spring-returned, valve

The valve shown is a normal1yclosed one only. When the valve is acetylated, air will flow through the 'out' port. The valve has two positions, viz, closed and' open.

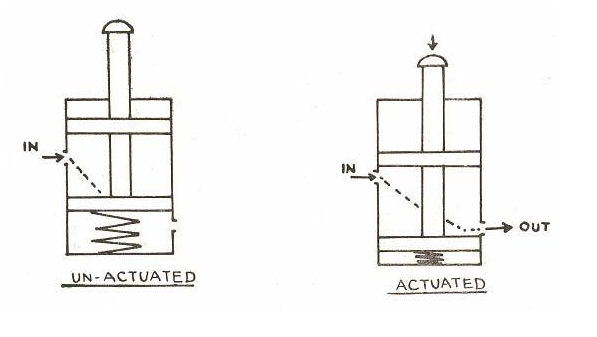

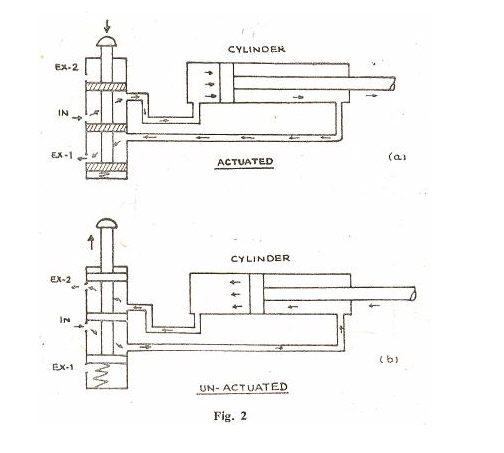

The application of a four-port valve to control a double acting cylinder is shown in the figure 2. This has actually five connections, Le; one inlet, two outlets and two exhaust ports. Figure 'a', shows the valve• in the actuated contrition. Aid lows from the in let port’ to the blind-end of the cylinder. As the piston moves forward, the air at the rod end is exhausted through exhaust port 1. Figure 'b' shows the valve in the un-actuated condition. Air is now diverted

to the rod end of the cylinder and the air discharged from the blind end is exhausted through the exhaust' port No.2.

Switches are devices which are used to make or break an electric circuit or to direct the current over desired paths. They may be operated manually, mechanically or by pneumatic, hydraulic or electro-magnetic means

These are momentary contact switches and are used to manually signal the start or stoppage of an operation which is electrically controlled. Generally, push button switches are capable of handling only small loads. ' At high loads, burning will occur at the points of contact, due to arcing. Since they are momentary contact switches, they do not have a memory of their own

A limit switch is generally actuated by a, mechanical device such a earn, moving part of a machine, etc. When actuated thus, it can make or break electrical connections.

These are electro-magnetically operated switches and are very useful in automatic control. A relay is used in switching circuits to 'amplify' signals, 'multiply' signals, to provide 'memory' and to 'invert' or 'convert' signals.

A photo-electric cell is a sensing device which can replace, to a curtain extent, human senses, in industrial operation and control. An automatic sensor is faster than a human being, and does not suffer from fatigue as human beings do. However, automatic sensors are not as discriminating add versatile as human beings are.

Photo-electric cells can be applied as simple on-off switches or to operate on a gradual change of light intensity.

A simple photo-electric cell consists of a light source and lens system to focus the light, and a receiver which comprises the photo-cell, an amplifier and a relay. The photo-electric cell can be 'dark-energised' or 'light-energised'. In the former, when the light beam is interrupted, the relay closes, while in the latter, the cell is normally in the dark and it will energise the relay when light falls on it.

In general terms, transducers are devices which convert one form of energy to another. They can be actuated by waves from one or more transmission systems or media and can supply related waves to one or more other transmission systems or media.

For example, we may consider the load cell which is a transducer, the electrical resistance of which varies with the load applied to it. This is basically, a strain gauge bonded to a steel cylinder. When a load is applied to the cylinder, the deformation caused is transmitted to the strain gauge, producing a charge in the electrical resistance of the wire. As long as the stress is not beyond the elastic limit, the change in the length of steel cylinder will be proportional to the applied load. As the change in resistance of the strain gauge is directly proportional to the change in the length of the cylinder, this acts as transducer producing a change of resistance directly proportional to the change in the load applied to the cell.

Load cells are used in automatic weighing.

This can be used as 'on-off' devices or to provide a variable control. Some of the applications include cutting steel strip to required lengths, using clutches and brakes for position control, precise control of speed of printing presses, automatic bar loading etc.

Pneumatic System Accessories! In pneumatic control circuits, the compressed air that is used should be cleansed, lubricated and, wherever necessary, de-humidified. The auxiliaries that are commonly used in pneumatic circuits include filters, lubricators, driers, air regulators and pressure gauges. A filter cleans the air of dirt and protects all the components using air. The regulator is used to regulate the air pressure so as to control the amount of thrust needed and also to provide for the safety and uniformity. The lubricator is used to provide proper lubrication. Air mufflers are used to reduce the level of noise of exhaust air and also for safety purposes in preventing dirt, chips etc., from being blown into the operator's face.

Hydraulic System Accessories! These include reservoirs, strainers and filters. Though the reservoir is meant for storage and supply of hydraulic system fluid, a properly designed reservoir assists in the separation of air and contaminants from the fluid and helps dissipation of heat generated within the system. The reservoir should be large enough to store more than the largest volume of fluid that the system will require. The reservoir capacity may be equal to two or three times the capacity per minute of the pumps.

Filters, strainers and magnetic plugs, are used to remove foreign particles from the fluid.