Work measurement refer to the estimation of standard time, that is the time allowed for completing one piece of job using the given method. This is the time taken by an average experienced worker for the job with provisions for delays beyond the workers control.

There are several techniques used for estimation of standard time in industry. These include time study, work sampling, standard data, and predetermined time systems.

Time study is a technique to estimate the time to be allowed to a qualified and well-trained worker working at a normal pace to complete a specified task.

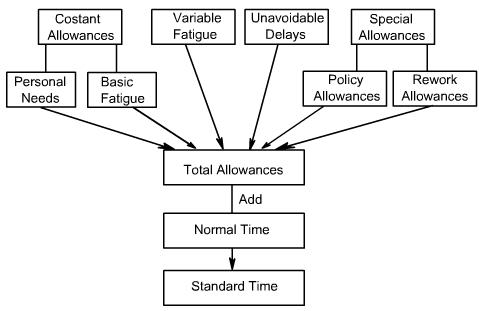

This technique is based on measuring the work content of the task when performed by the prescribed method, with the allowance for fatigue and for personal and unavoidable delays.

Standard times for different operations in industry are useful for several applications like

Time Study is the most versatile and the most widely used.

The following equipment is needed for time study work

The stop watch (Figure1) and the electronic timer are the most widely used timing devices used for time study. The two perform the same function with the difference that electronics timer can measure time to the second or third decimal of a second and can keep a large volume of time data in memory

It is a printed form with space provided for nothing down the necessary information about the operation being studied like name of operation, drawing number, name of the operator, name of time study person, and the date and place of study. Space are provided in the form for writing detailed description of the process (element-wise), recording stop-watch readings for each element of the process, performance rating(s) of the operator, and computation Figure 2 Shows a typical time study observation sheet.

It is a light -weight board used for holding the observation sheet and stopwatch in position. It is of size slightly larger than that of observation sheet used. Generally, the watch is mounted at the center of the top edge or as shown in Figure 3 near the upper right-hand corner of the board. The board has a clamp to hold the observation sheet. During the time study, the board is held against the body and the upper left arm by the time study person in such a way that the watch could be operated by the thumb/index finger of the left hand. Watch readings are recorded on the observation sheet by the right hand.

This includes pencil, eraser and device like tachometer for checking the speed, etc

The procedure for time study can best be described step-wise, which are self explanatory.

Step 1: Define objective of the study. This involves statement of the use of the result, the preci9sion desired, and the required level of confidence in the estimated time standards.

Step 2: Analyse the operation to determine whether standard method and conditions exist and whether the operator is properly trained. If need is felt for method study or further training of operator, the same may be completed before starting the time study.

Step 3: Select Operator to be studied if there is more than one operator doing the same task.

Step 4: Record information about the standard method, operation, operator, product, equipment, quality and conditions.

Step 5: Divide the operation into reasonably small elements.

Step 6: Time the operator for each of the elements. Record the data for a few number of cycles. Use the data to estimate the total numbers of observations to be taken.

Step 7: Collect and record the data of required number of cycles by timing and rating the operator.

Step 8: For each element calculate the representative watch time. Multiply it by the rating factory to get normal time.

Normal time = Observed time * Rating factor

Add the normal time of various elements to obtain the normal time for the whole operation.

Step 9: Determine allowances for various delays from the company's policy book or by conducting an independent study.

Step 10: Determine standard time by adding allowances to the normal time of operation.

Standard time = Normal time + allowances

There is no universal concept of Normal Performance. However, it is generally defined as the working rate of an average qualified worker working under capable supervision but not under any incentive wage payment scheme. This rate of working is characterized by the fairly steady exertion of reasonable effort, and can be maintained day after day without undue physical or mental fatigue.

The level of normal performance differs considerably from one company to another. What company A calls 100 percent performance, company B may call 80 percent, company C may call 125 percent and so on. It is important to understand that the level that a company selects for normal performance is not critical but maintaining that level uniform among time study person and constant with the passage of time within the company is extremely important.

There are, of course, some universally accepted benchmark examples of normal performance, like dealing 52 cards in four piles in 0.5 minute, and walking at 3 miles per hour (4.83 km/hr). In order to make use of these benchmarks, it is important that a complete description about these be fully understood, like in the case of card dealing, what is the distance of each pile with respect to the dealer, technique of grasping, moving and disposal of the cards.

Some companies make use of video films or motion pictures for establishing what they consider as normal speed or normal rate of movement of body members. Such films are made of typical factory jobs with the operator working at the desired normal pace. These films are reported to be useful in demonstrating the level of performance expected from the operators and also for training of time study staff.

During the time study, time study engineer carefully observes the performance of the operator. This performance seldom conforms to the exact definition of normal or standard. Therefore, it becomes necessary to apply some 'adjustment' to the mean observed time to arrive at the time that the normal operator would have needed to do that job when working at an average pace. This 'adjustment' is called Performance Rating.

Determination of performance rating is an important step in the work measurement procedures. It is based entirely on the experience, training, and judgment of the work-study engineer. It is the step most subjective and therefore is subject to criticism.

It is the procedure in which the time study engineer compares the performance of operator(s) under observation to the Normal Performance and determines a factor called Rating Factor

![]()

There are several systems of rating, the performance of operator on the job. These are

A brief description of each rating method follows

Under this system, performance is evaluated by considering the rate of accomplishment of the work per unit time. The study person measures the effectiveness of the operator against the concept of normal performance and then assigns a percentage to indicate the ratio of the observed performance to normal or standard performance.

In this method, which is also called the speed rating method, the time study person judges the operators speed of movements, i.e. the rate at which he is applying himself, or in other words "how fast" the operator the motions involved.

This method considers four factors in evaluating the performance of the operator : Skill, effort, conditions and Consistency.

Skill may be defined as proficiency at following a given method. It is demonstrated by co ordination of mind and hands. A person's skill in given operation increases with his experience on the job, because increased familiarity with work bring speed, smoothness of motions and freedom from hesitations.

The Westing house system lists six classes of skill as poor fair, average, good, excellent in aTable1. The time study person evaluates the skill displayed by the operator and puts it in one of the six classes. As equipment % value of each class of skill is provided in the table, the rating is translated into its equivalent percentage value, which ranges from +15 % (for super skill) to - 22 % (for poor skill).

In a similar fashion, the ratings for effort, conditions, and consistency are given usingTable2 for each of the factors. By algebraically combining the ratings with respect to each of the four factors, the final performance-rating factor is estimated.

In this system, speed of movements and job difficulty are rated separately and the two estimates are combined into a single value. Rating of speed or pace is done as described earlier, and the rating of job difficulty is done by selecting adjustment factors corresponding to characteristics of operation with respect to (i) amount of body used, (ii) foot pedals, (iii) bimanual ness, (iv) eye-hand co ordination, (v) handling requirements and (vi) weight handled or resistance encountered Mundel and Danner have given Table3 of % values (adjustment factor) for the effects of various difficulties in the operation performed.

For an operation under study, the numerical value for each of the six factors is assigned, and the algebraic sum of the numerical values called job difficulty adjustment factor is estimated.

The rating factor R can be expressed as

R = P x D

Where : P = Pace rating factor

D = Job difficulty adjustment factor.

This method of rating has two main advantages over other methods that (i) it does not rely on the judgment of the time study person and (ii) it give consistent results.

The time study is made as usual. Some manually controlled elements of the work cycle are selected. Using a PMT system (Pre- determined motion time system), the times for these elements are determined. The times of these elements are the performance factor is determined for each of the selected elements.

Performance or Rating Factor, R = P / A

Where P = Predetermined motion time of the element , A = Average actual Observed time of the element.

The overall rating factor is the mean of rating factors determined for the selected elements, which is applied uniformly to all the manually controlled elements of the work cycle.

A work cycle has been divided into 8 elements and time study has been conducted. The average observed times for the elements are as :

M = Manually Controlled , P = Power Controlled

Total observed time of work cycle = 2.32 min.

Suppose we select elements number 2,5 and 8 (These must be manual y controlled elements). By using some PMT system, suppose we determine the times of these elements as

The mean of the rating factors of selected elements = 94.93 % or say95 % is the rating factor that will be used for all the manual elements of the work cycle.

The normal time of the cycle is calculated as given in the following table.

Normal Cycle Time

= 0.95(0.14+0.16+0.52+0.26+0.45+0.34+0.15)+1.00(0.30)

=1.92+0.30

=2.22 minutes

In this procedure, we estimate the allowance for arriving the standard data.

Allowances

The readings of any time study are taken over a relatively short period of time. The normal time arrived at, therefore does not include unavoidable delay and other legitimate lost time, for example, in waiting for materials, tools or equipment; periodic inspection of parts; interruptions due to legitimate personal need, etc. It is necessary and important that the time study person applies some adjustment, or allowances to compensate for such losses, so that fair time standard is established for the given job.

Allowances are generally applied to total cycle time as some percentage of it, but sometimes these are given separately as some % for machine time and some other % for manual effort time. However no allowance are given for interruptions which maybe due to factor which are within the operator's control or which are avoidable.

Most companies allow the following allowances to their employees.

This time allowance is given to an operator for the numerous interruptions that he experiences every day during the course of his work. These interruptions include interruptions from the supervisor, inspector, planners, expediters, fellow workers, production personnel and others. This allowance also covers interruptions due to material irregularities, difficulty in maintaining specifications and tolerances, and interference delays where the operator has to attend to more than one machine.

This allowance can be divided into two parts: (i) basic fatigue allowance and (ii) variable fatigue allowance. The basic fatigue allowance is given to the operator to compensate for the energy expended for carrying out the work and to alleviate monotony. For an operator who is doing light work while seated, under good working conditions and under normal demands on the sensory or motor system, a 4% of normal time is considered adequate. This can be treated as a constant allowance.

The magnitude of variable fatigue allowance given to the operator depends upon the severity of the factor or conditions, which cause extra (more than normal) fatigue to him. As we know, fatigue is not homogeneous, it range from strictly physical to purely psychological and includes combinations of the two. on some people it has a marked effect while on others, it has apparently little or no effect. Whatever may be the kind of fatigue-physical or mental, the result is same-it reduces the work output of operator. The major factors that cause more than just the basic fatigue includes sever working conditions, especially with respect to noise, illumination, heat and humidity; the nature of work, especially with respect to posture, muscular exertion and tediousness and like that.

It is true that in modern industry, heavy manual work, and thus muscular fatigue is reducing day by day but mechanization is promoting other fatigue components like monotony and mental stress. Because fatigue in totality cannot be eliminated, proper allowance has to be given for adverse working conditions and repetitiveness of the work.

This is allowed to compensate for the time spent by worker in meeting the physical needs. A normal person requires a periodic break in the production routine. The amount of personal time required by operator varies with the individual more than with the kind of work, though it is seen that workers need more personal time when the work is heavy and done under unfavorable conditions.

The amount of this allowance can be determined by making all-day time study or work sampling. Mostly, a 5 % allowance for personal time (nearly 24 minutes in 8 hours) is considered appropriate.

These allowances are given under certain special circumstances. Some of allowances and the conditions under which they are given are:

Small Lot Allowance: This allowance is given when the actual production period is too short to allow the worker to come out of the initial learning period. When an operator completes several small-lot jobs on different setups during the day, an allowance as high as 15 percent may be given to allow the operator to make normal earnings.

Training Allowance: This allowance is provided when work is done by trainee to allow him to maker reasonable earnings. It may be a sliding allowance, which progressively decreases to zero over certain length of time. If the effect of learning on the job is known, the rate of decrease of the training allowance can be set accordingly.

Rework Allowance: This allowance is provided on certain operation when it is known that some present of parts made are spoiled due to factors beyond the operator's control. The time in which these spoiled parts may be reworked is converted into allowance.

Different organizations have decided upon the amount of allowances to be given to different operators by taking help from the specialists / consultants in the field and through negotiations between the management and the trade unions. ILO has given its recommendations about the magnitude of various allowances, Table 4.

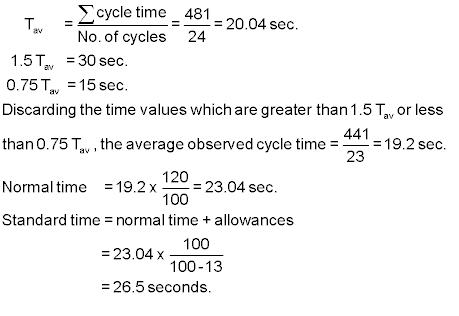

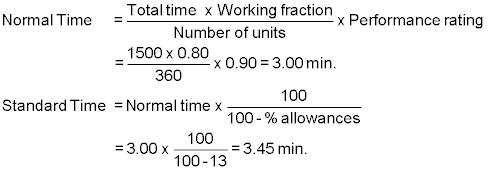

In making a time study of a laboratory technician performing an analysis of processed food in a canning factory, the following times were noted for a particular operation.

If the technician's performance has been rated at 120 percent, and the company policy for allowance (personal, fatigue, etc.) stipulates 13 percent.

Watch readings falling 50 % above and 25 % below the average may be considered as abnormal.

Ans :

Work Sampling (also sometimes called ratio delay study) is a technique of getting facts about utilization of machines or human beings through a large number of instantaneous observations taken at random time intervals. The ratio of observations of a given activity to the total observations approximates the percentage of time that the process is in that state of activity. For example, if 500 instantaneous observations taken at random intervals over a few weeks show that a lathe operator was doing productive work in 365 observations and in the remaining 135 observations he was found 'idle' for miscellaneous reasons, then it can be taken that the operator remains idle (135/500) x 100 = 27 % 0f the time. Obviously, the accuracy of the result depends on the number of observations. However, in most applications there is usually a limit beyond which greater accuracy of data is not economically worthwhile

Work sampling can be very useful for establishing time standards on both direct and indirect labor jobs. The procedure for conducting work sampling study for determining standard time of a job can be described step-wise.

Step 1. Define the problem. (i) Describe the job for which the standard time is to be determined. (ii) Unambiguously State and discriminate between the two classes of activities of operator on the job: what are the activities of job with which if operator is found engaged would entitle him to be in 'working" state. This would imply that when operator will be found engaged in any activity other than those would entitle him to be in "Not Working" state.

Step 2. Design the Sampling plan. (i) Estimate satisfactory number of observations to be made. (ii) Decide on the period of study, e.g. two days, one week, etc. (iii) Prepare detailed plan for taking the observations. This will include observation schedule, exact method of observing, design of observation sheet route to be followed, the particular person to be observed at the observation time, etc.

Step 3. Contact the person concerned and take them in confidence regarding conduct of the study.

Step 4. Collect the data at the pre-decided random times.

We will now briefly discuss some important issues involved in the procedure.

As we know, result of study based on larger number of observations are more accurate, but taking more and more observation consume time and thus is costly. A cost-benefit trade-off has thus to be struck. In practice, the following methods are used for estimation of the number of observation to be made.

(i) Based on judgment. The study person can decide the necessary number of observations based on his judgment. The correctness of the number may be in doubt but estimate is often quick and adequate in many cases.

(ii) Using cumulative plot of results. As the study progresses the results (of the proportion of time devoted to the given activity, i.e. Pi from the cumulative number of observations are plotted at the end of each shift or day. A typical plot is shown in Figure4. Since the accuracy of the result improves with increasing number of observation, the study can be continued until the cumulative Pi appears to stabilize and collection of further data seems to have negligible effect on the value of Pi.

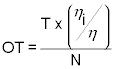

(iii) Use of statistics. In this method, by considering the important of the decision to be based on the results of study, a maximum tolerable sampling error in terms of confidence level and desired accuracy in the results is specified. A pilot study is then made in which a few observations are taken to obtain a preliminary estimate of Pi. The number of observations N necessary are then calculated using the following expression.

![]()

Where S = desired relative accuracy

Pi = estimate of proportion of time devoted to activity expressed as a decimal,

e.g. 5 % = 0.05

χ = a factor depending on the confidence level.

χ = 1, 2, 3 for confidence levels of 68 %, 95 % and 99 % respectively.

N = total number of observations needed.

The number of observations estimated from the above relation using a value of Pi obtained from a preliminary study would be only a first estimate. In actual practice, as the work sampling study proceeds, say at the end of each day, a new calculation should be made by using increasingly reliable value of Pi obtained from the cumulative number of observations made.

The number of instantaneous observations to be made each day mainly depends upon nature of operation. For example, for non-repetitive operations or for operations in which some elements occur in frequently, it is advisable to take observations more frequently so that the chance of obtaining all the facts improves. It also depends on the availability of time with the person making the study. In general, about 50 observations per day is a good figure. The exact (random) schedule of the observations is prepared by using random number table or any other technique.

A sample observation sheet for recording the data with respect to whether at the pre-decided time, the worker on job is in 'working' state or 'non-working' state is shown in figure5. It contains the relevant information about the job, the operators on job, etc. At the end of each day, calculation can be done on the percent of time workers on the job (on an average) spend on activities, which are considered as part of the work method

In this method of work measurement, the observed time for a given job is estimated as the working time divided by the number of units produced during that time.

Where T = Total study period

N = Number of units produced in study period

ηi =Number of observations in which worker(s) was found in 'working' state

ηi =Number of observations in which worker(s) was found in 'working' state

The normal time (NT) is found by multiplying the observed time by the average performing index (rating factor).

![]()

Where= Average rating factor = ![]()

Finally, the standard time is found by adding allowances to the normal time.

A work sampling study was made of a cargo loading operation for the purpose of developing its standard time. The study was conducted for duration of minutes during which 3000, 1500 instantaneous observations were made at random intervals. The results of study indicated that the worker on the job was working 80 percent of the time and loaded 360 pieces of cargo during the study period. The work analyst rated the performance at 90 %. If the management wishes to permit a 13 % allowance for fatigue, delays and personal time, what is the standard time of this operation?

Here, Total period = 1500 minutes

Working fraction = 80 percent

Average rating = 90 percent

Number of units loaded = 360

Allowances = 13 %

Advantages and Disadvantages of Work Sampling in Comparison with Time Study.

Economical

Observations may be taken over a period of days or weeks. This decreases the chance of day-to-day or week-to-week variations that may affect the results.

Work sampling studies are preferred to continuous time study by the operators being studied. Some people do not like to be observed continuously for long periods of time.

Work sampling studies are less fatiguing and less tedious to make on the part of time study engineer.

Work sampling is applicable to a wide variety of situations in manufacturing, distribution, or service industries.

Work sampling is useful when determine the nature of the distribution of work activities within a gang operation.

Use of a computer can save as much as 30 to 40 percent of the total work sampling study cost. This is because too much clerical effort is involved in summarizing work sampling data, e.g. in determining the number of observations required, determining the daily observations required, determining the number of trips to the area being studied per day, determining the time of each observation, calculating the accuracy of results, plotting data on control charts and like that. Computers can be made use for mechanization of the repetitive calculations, display of control charts and calculation of daily as well as cumulative results.

A predetermined motion time system (PMTS) may be defined as a procedure that analyzes any manual activity in terms of basic or fundamental motions required to performing it. Each of these motions is assigned a previously established standard time value in such a way that the timings for the individual motions can be synthesized to obtain the total time for the performance of the activity.

The main use of PMTS lies in the estimation of time for the performance of a task before it is performed. The procedure is particularly useful to some organizations because it does not require troublesome rating with each study.

Applications of PMTS are for

Estimation of manpower, equipment and space requirements prior to setting up the facilities and start of production.

Developing tentative work layouts for assembly line prior to their working.

Checking direct time study results.

A number of PMTS are in use, some of which have been developed by individual organizations for their own use, while other organizations have publicized for universal applications.

The following are commonly used PMT systems

Some important factors which be considered while selecting a PMT system for application to particular industry are

Compared to other work measurement techniques, all PMT system claim the following advantages:

There are two main limitations to the use of PMT system for establishing time standards. These are : (i) its application to only manual contents of job and (ii) the need of trained personnel. Although PMT system eliminates the use of rating, quite a bit of judgment is still necessarily exercised at different stages.